The realm of manufacturing has been significantly influenced by the diverse and sophisticated techniques of casting processes. This article explores ten prominent casting methods that have become integral to the production of various components, from intricate automotive parts to complex industrial machinery.

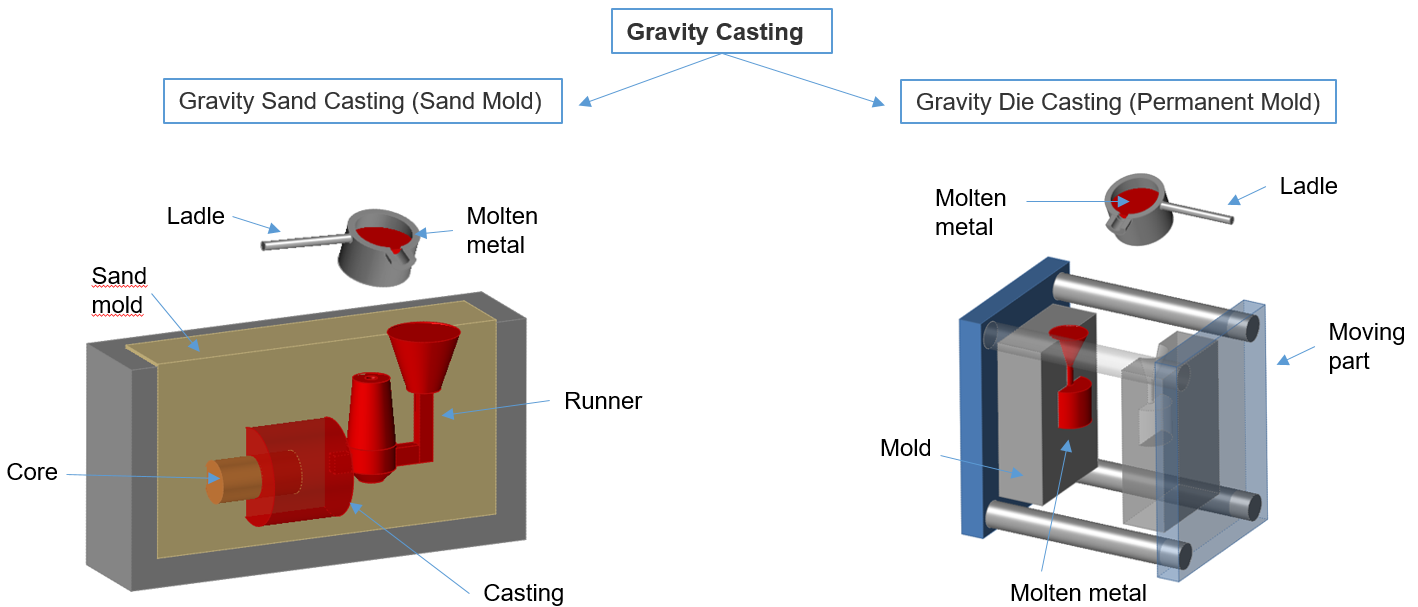

Sand casting is a casting method that produces castings in sand molds. It is suitable for shaping complex forms, especially blanks with intricate internal cavities. Widely used for steel, iron, and most non-ferrous alloy castings.

Suitable for shaping complex and intricately cored blanks.

Broad adaptability with low costs.

Ideal for materials with poor plasticity, such as cast iron.

Used in the production of automotive engine cylinder heads, cylinder blocks, crankshafts, and other castings.

Investment casting, also known as "lost wax casting," involves creating a mold from a pattern made of easily meltable material, forming a refractory shell around it, and then melting the pattern to obtain a mold for casting.

High dimensional and geometric accuracy.

Suitable for casting complex-shaped parts.

Applicable to various alloys.

Complex processes and higher costs.

Ideal for producing small parts with complex shapes and high precision, such as turbine engine blades.

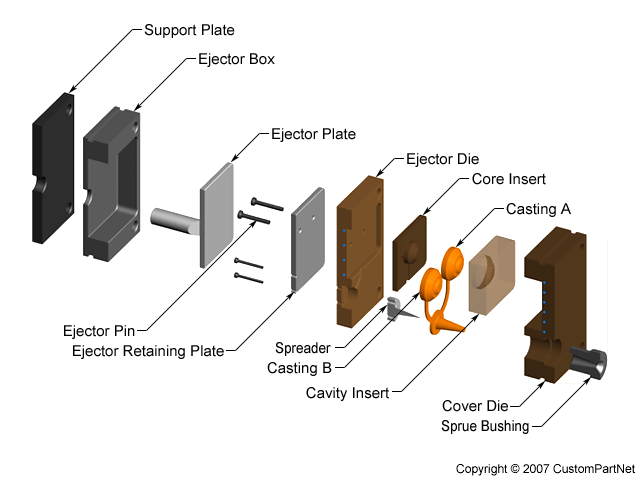

Die casting utilizes high pressure to inject molten metal into a precise mold cavity, resulting in the rapid cooling and solidification of the metal to form a casting.

High pressure and fast metal flow during casting.

Excellent product quality, stability in dimensions, and interchangeability.

High production efficiency, suitable for large-scale production.

Prone to small pores and shrinkage.

Limited plasticity, not suitable for impact loads.

Initially applied in automotive and instrumentation industries, later expanded to various sectors.

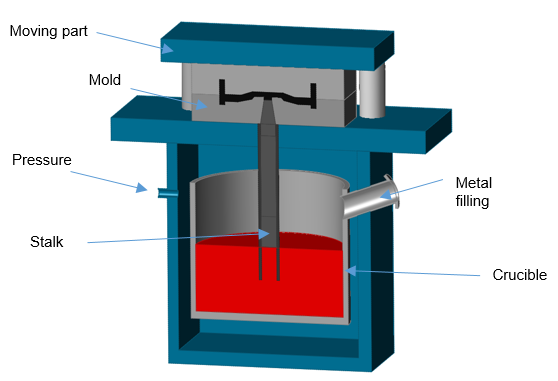

Low-pressure casting involves filling the mold with liquid metal at lower pressures (0.02-0.06 MPa) to create castings.

Adjustable pressure and speed for various molds and alloys.

Smooth metal filling without splashing.

Suitable for casting large and thin-walled parts.

Mainly used for traditional products like cylinder heads, wheel hubs, and cylinder blocks.

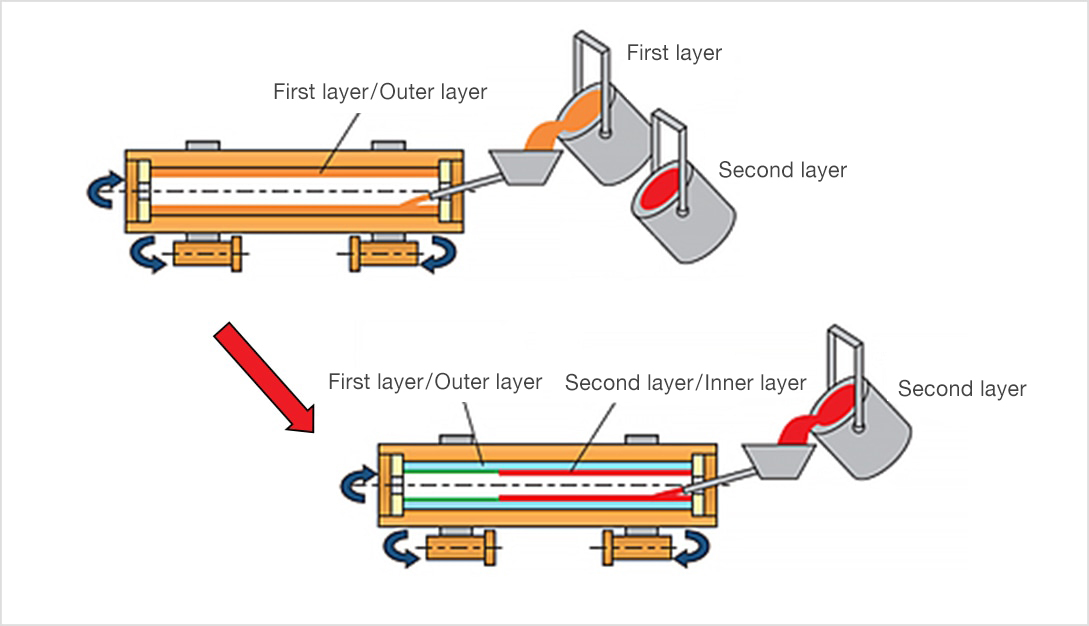

Centrifugal casting is a method where molten metal is poured into a rotating mold, utilizing centrifugal force to fill the mold and solidify the metal.

Minimal metal consumption without gating and riser systems.

Suitable for producing hollow castings without cores.

High casting density, low defects, and high mechanical properties.

Limitations in producing complex-shaped castings.

Inaccurate inner hole diameter with rough surfaces.

Widely used in metallurgy, mining, transportation, aviation, defense, and automotive industries.

Gravity die casting involves filling a metal mold with liquid metal under gravity to achieve casting formation.

High thermal conductivity of the metal mold for fast cooling.

High dimensional accuracy and low surface roughness.

Reduced environmental impact and labor intensity.

Requires measures to eliminate air and gas generated during casting.

No flexibility in the metal mold.

Suitable for large-scale production of aluminum, magnesium, and other non-ferrous alloy castings.

Vacuum die casting involves removing gases from the die cavity during the die casting process to eliminate or significantly reduce porosity and dissolved gases in the casting.

Improved mechanical properties and surface quality.

Lower back pressure allows the use of lower pressure and poorer casting alloys.

Enhanced filling conditions for thinner castings.

Complex mold sealing structure with higher manufacturing costs.

Effectiveness depends on proper control.

Squeezing die casting involves solidifying or flow-forming liquid or semi-solid metal under high pressure to directly obtain finished parts or blanks.

Direct squeezing die casting: Spraying, pouring, molding, pressurizing, maintaining pressure, depressurizing, demolding, and resetting.

Eliminates internal defects like pores and shrinkage.

Low surface roughness, high dimensional accuracy.

Prevents the formation of casting cracks.

Suitable for producing various alloys such as aluminum, zinc, copper, and nodular cast iron.

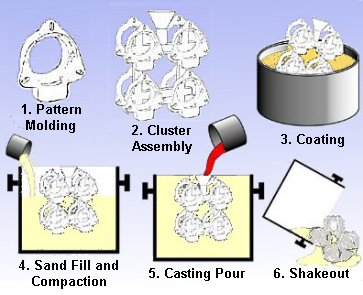

Lost foam casting involves creating a cluster of wax or foam models similar in size and shape to the casting, coating them with refractory material, and casting them in dry quartz sand.

High casting precision with no cores, reducing processing time.

No parting line, offering design flexibility.

Clean production, no pollution.

Reduces investment and production costs.

Suitable for complex and precision castings, regardless of alloy type or production volume.

Continuous casting is an advanced casting method where molten metal is continuously poured into a special metal mold called a crystallizer, and the solidified castings are continuously pulled out from the other end.

Rapid cooling results in dense and uniform structures.

Saves metal and increases yield.

Simplifies processes, reduces labor intensity, and enables mechanization.

Used to cast unchanging cross-sectional shapes of long castings, such as ingots, slabs, rods, and tubes, in steel, iron, copper alloy, aluminum alloy, and magnesium alloy production.

In conclusion, the world of casting processes is diverse and rich, offering a spectrum of techniques tailored to meet the specific requirements of different industries. As technology advances, these casting methods continue to evolve, ensuring enhanced efficiency, higher quality, and expanded possibilities in the realm of metal shaping. For more information on casting technologies and metal solutions, contact us.