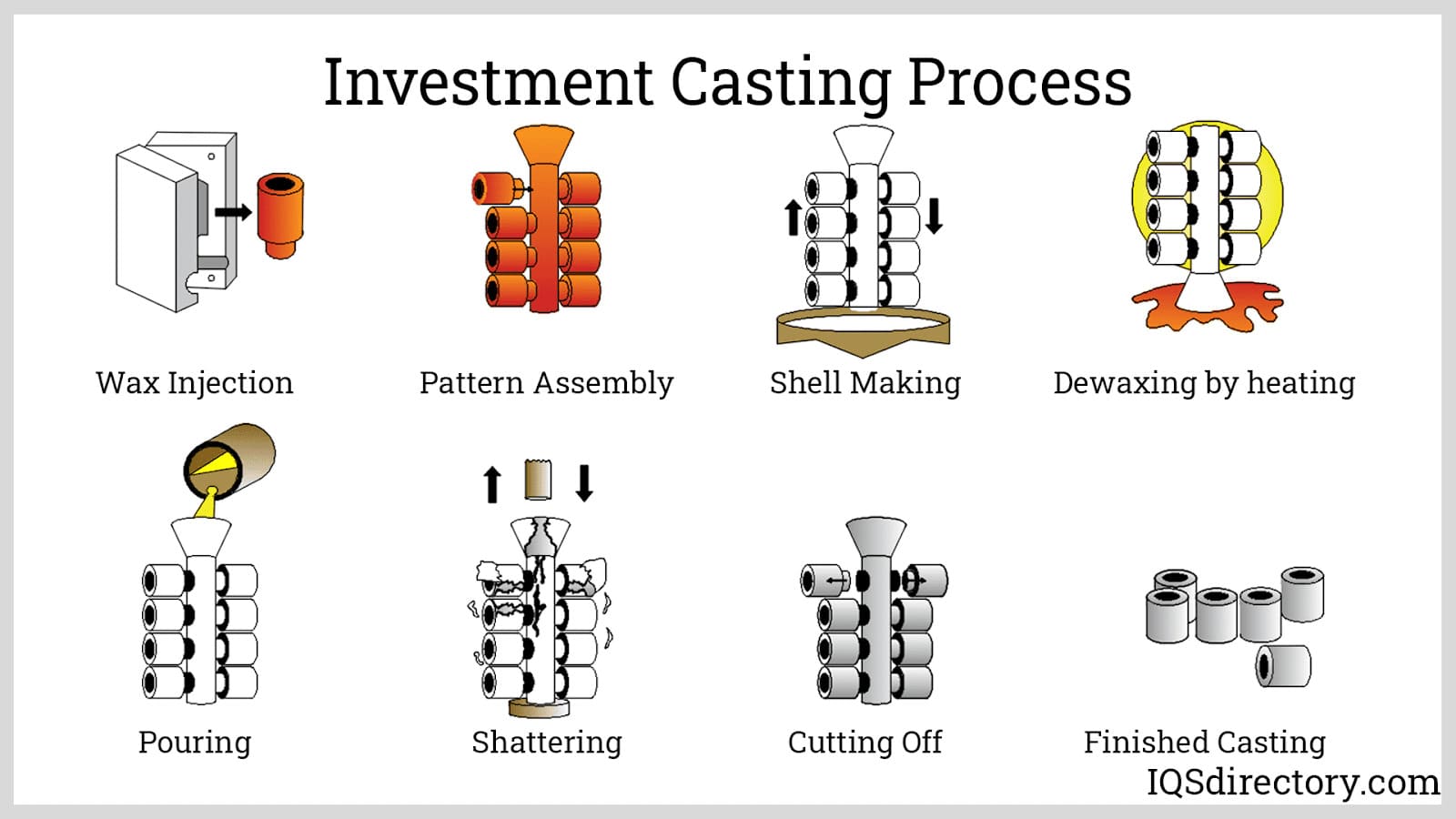

Investment casting is a precision casting process that utilizes melted wax patterns to create intricate metal components. In investment casting, the first step involves manufacturing a wax pattern that closely resembles the final metal component. This wax pattern is created by injecting molten wax into a mold, often based on CAD designs. The quality and precision of the wax pattern directly impact the quality and precision of the final casting.

Wax patterns can easily form complex internal and external shapes, allowing investment casting to produce various intricate components such as turbine blades and turbine casings.

The smoothness and accuracy of the wax pattern surface determine the surface quality of the final casting. High-quality wax patterns can produce highly accurate casting surfaces, reducing the need for subsequent machining processes.

Wax patterns can also create components with intricate internal structures, such as internal channels and cavities, which are challenging to achieve with traditional casting processes.

Wax patterns serve as the initial form of the casting model, closely replicating the shape and dimensions of the final casting, providing the mold for subsequent casting steps.

The manufacturing process of wax patterns allows for precise control of casting dimensions and shapes, ensuring the accuracy and quality of the final casting.

Wax patterns act as molds, supporting and stabilizing components during the casting process, ensuring the stability and accuracy of the casting process.

Wax patterns support and fix components during the casting process, ensuring the stability and accuracy of the casting process.

Therefore, wax patterns play an indispensable role in investment casting, with their quality and precision directly impacting the quality and performance of the final castings. Fine control over the design, manufacturing, and use of wax patterns is crucial for the success of investment casting processes.

If you want to know more about precision casting related technologies, please feel free to contact us.

Other related articles:

What Type of Wax Is Typically Used in Investment Casting