In the realm of manufacturing, precision casting stands out as a critical process for producing intricate metal components with high accuracy and quality. However, despite its advantages, precision casting encounters various challenges that can hinder production efficiency and product quality. Common issues that may arise during the precision casting process include gas porosity, shrinkage porosity, cracks, and more. These issues have the potential to affect the quality and performance of the products.

Gas porosity is a common problem in precision casting, occurring when gas cannot be completely removed from the liquid metal, resulting in the formation of voids. To address gas porosity, it's crucial to ensure the cleanliness of the mold and the surface of the molten metal. Techniques such as vacuum casting or pressure casting are employed to remove gases. Additionally, controlling the pouring speed and temperature are important measures to reduce the formation of gas porosity.

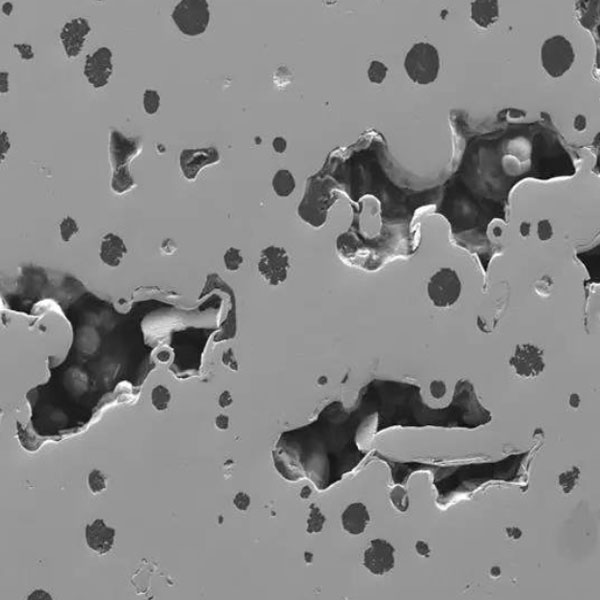

Another common issue is shrinkage porosity, which occurs due to the shrinkage of casting material during solidification, leading to the formation of holes. The key to solving shrinkage porosity lies in optimizing casting design, adding appropriate gating systems and risers, and adjusting casting process parameters to minimize shrinkage and ensure the integrity of the castings.

Cracks are another potential problem, usually caused by stress concentration or thermal stress exceeding the material's capacity. To address crack formation, optimization of casting design, control of cooling rates, and selection of materials with good mechanical properties and resistance to stress cracking are essential. Additionally, using preheating and post-processing techniques are effective methods to reduce cracks.

Apart from the aforementioned problems, precision casting processes may also encounter surface defects and foreign material inclusions. The key to solving these issues lies in improving mold surface quality, enhancing raw material purification, and implementing effective quality control and monitoring measures to ensure stable and reliable casting quality.

In addressing these issues, it is essential to comprehensively analyze each stage of the casting process and implement integrated improvement measures, including material selection, optimization of process parameters, equipment upgrades, and enhancement of operational techniques. Continuous quality control and monitoring are also vital in ensuring stable quality in precision casting.

For more information and expert guidance on precision casting solutions, feel free to contact us.